The cockpit area gets reinforced with four feet of fiberglass cloth covering the entire cockpit area, then an additional 22″ X 13″ piece of fiberglass cloth goes over the deck recess area. Also, three layers of fiberglass are laminated across the underside of the deck, right in front of the cockpit opening to reinforce the deck.

The manual said the the easiest way to remove the temporary frames, which had been glued into the hull with a hot glue gun before the wires were removed, was to reheat the glue with the gun or a soldering iron. I tried that on a couple of the beads of glue and found it to be kind-of time consuming and messy. So instead, I used a sharp utility knife and carefully ran the tip of the blade between the hull and the bead of glue. I then gave the frames a little wiggle, and hey presto!, the frames came out. The residual glue on the hull easily came off with a putty knife. MUCH easier than reheating the glue if you ask me. The next steps for the hull will be filling the seams, and encasing the inside of the hull in fiberglass in the same way that the outside was done.

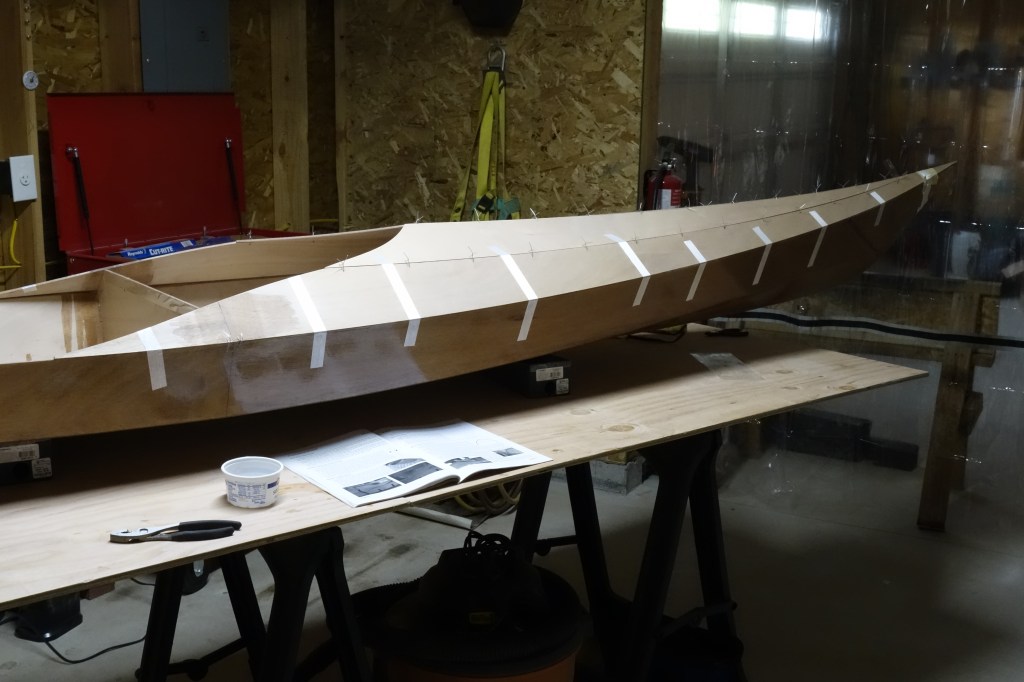

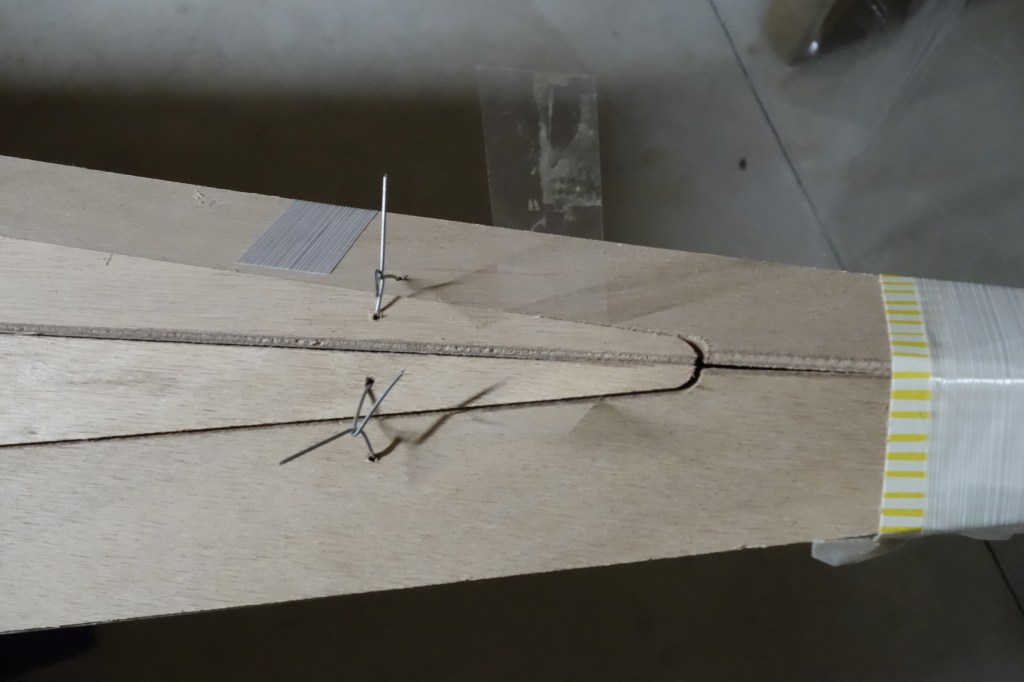

With the outside of the hull finished, construction of the deck can begin. The deck panels have been drilled in much the same way as the hull panels were, and will be stitched together atop the temporary frames in the hull. The spacers that were screwed to the frames during hull construction have been removed so now the frames will guide the shape of the deck as it is wired together.

The hull will get three fill coats of epoxy. It will also get a sacrificial strip of fiberglass tape that will run the length of the hull and most of the way up the bow and stern stems. This tape will provide protection to the keel of the kayak when beaching the boat on sandy or rocky shores. This strip will get replaced/renewed every few years when the kayak gets refinished.

One of the wonderful things about building a kayak that is a composite of wood and fiberglass is that the end result is stronger than either wood, or fiberglass by itself. Another benefit is that a wood and fiberglass kayak will not sink, even if you fill the whole kayak with water! A fiberglass boat without supplemental flotation will sink like a stone if filled with water.