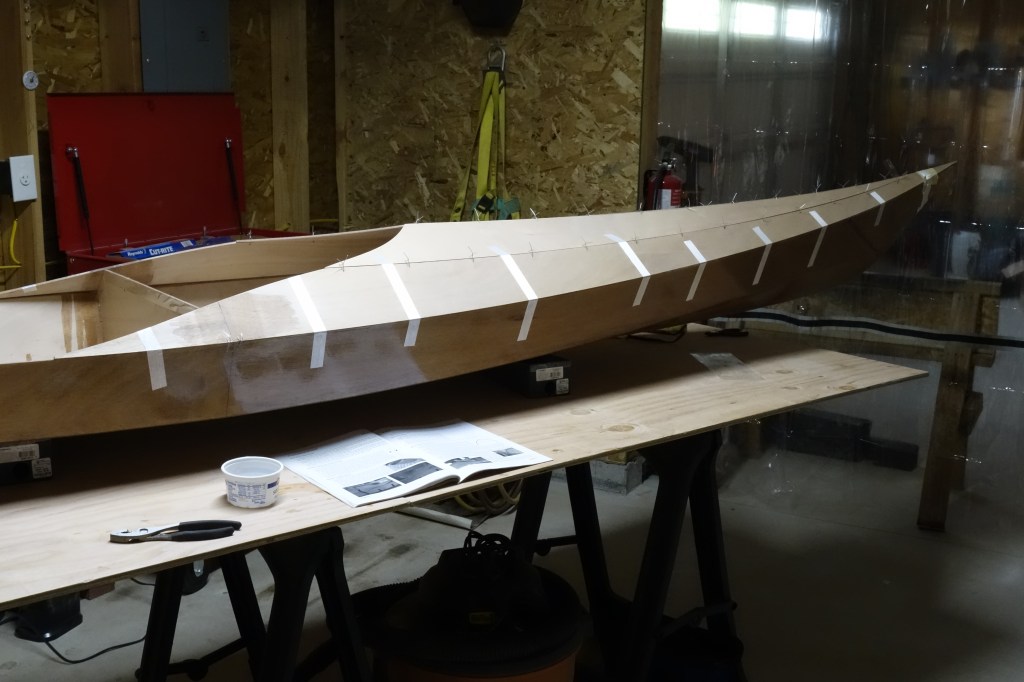

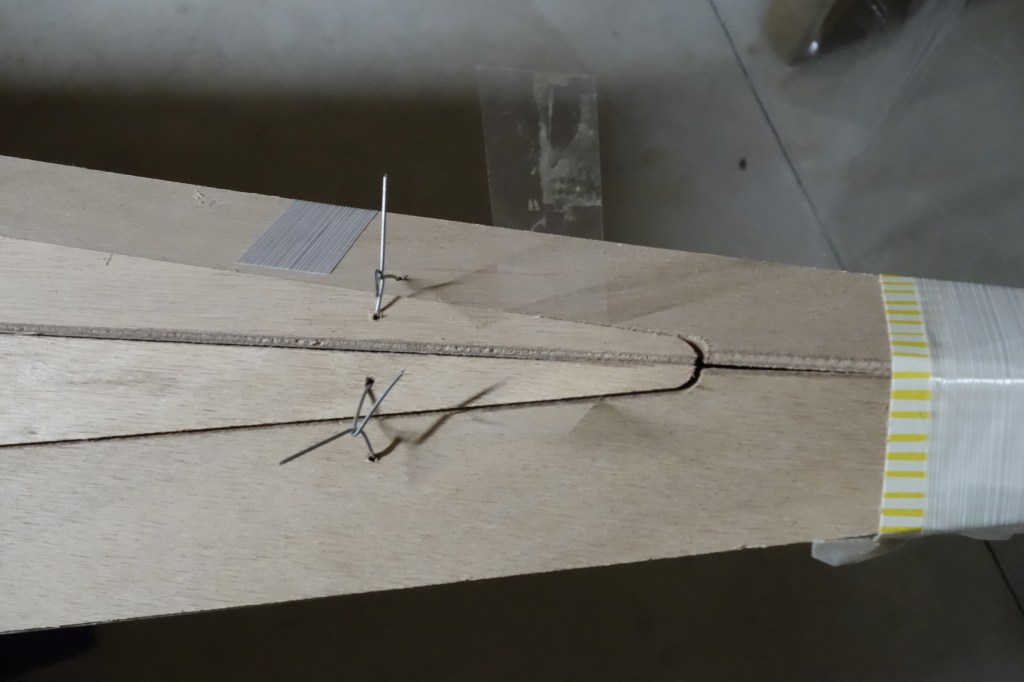

With the outside of the hull finished, construction of the deck can begin. The deck panels have been drilled in much the same way as the hull panels were, and will be stitched together atop the temporary frames in the hull. The spacers that were screwed to the frames during hull construction have been removed so now the frames will guide the shape of the deck as it is wired together.

The hull will get three fill coats of epoxy. It will also get a sacrificial strip of fiberglass tape that will run the length of the hull and most of the way up the bow and stern stems. This tape will provide protection to the keel of the kayak when beaching the boat on sandy or rocky shores. This strip will get replaced/renewed every few years when the kayak gets refinished.

One of the wonderful things about building a kayak that is a composite of wood and fiberglass is that the end result is stronger than either wood, or fiberglass by itself. Another benefit is that a wood and fiberglass kayak will not sink, even if you fill the whole kayak with water! A fiberglass boat without supplemental flotation will sink like a stone if filled with water.