Major milestone. Gluing the deck to the hull! The kayak will be one piece by the end of the day.

Major milestone. Gluing the deck to the hull! The kayak will be one piece by the end of the day.

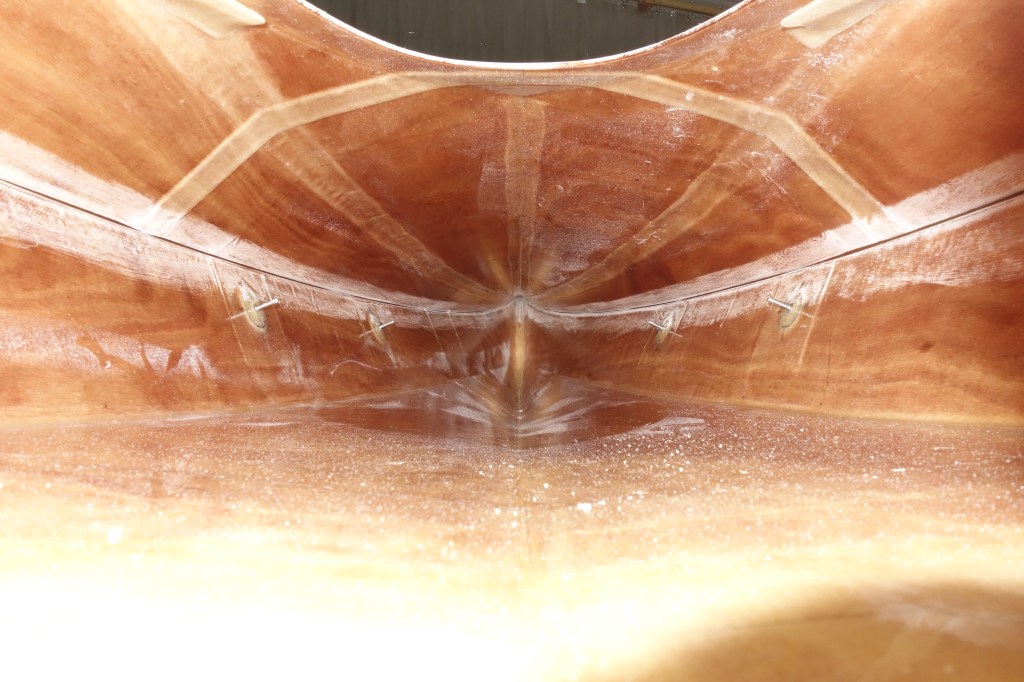

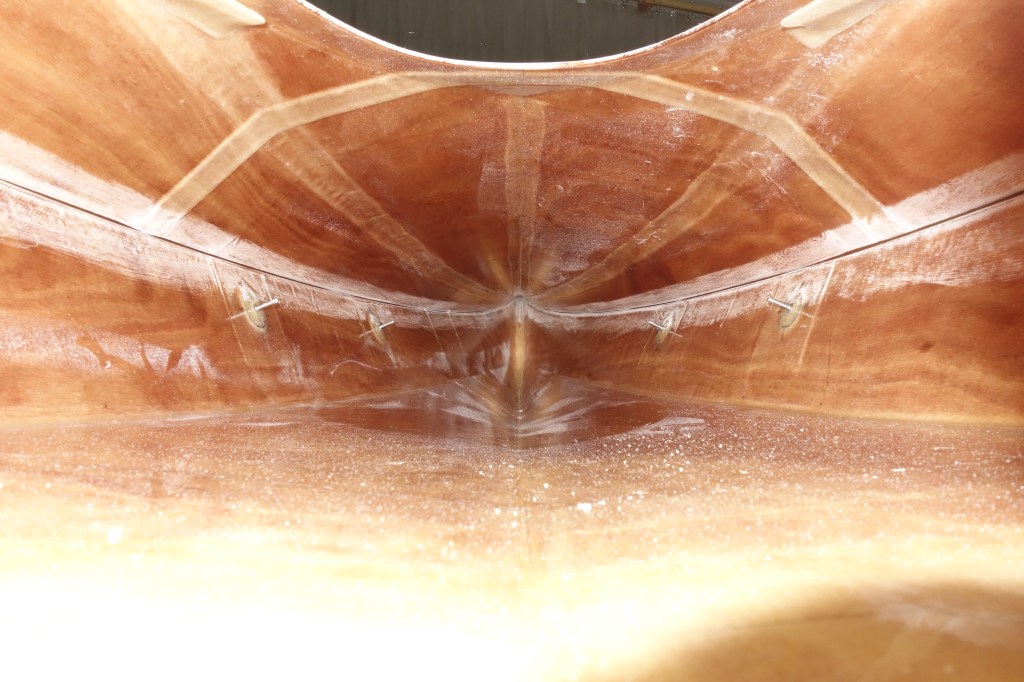

Rather than eventually drilling holes through the hull to mount the foot brace rails, Pygmy offers optional foot brace studs that are epoxied and fiberglassed to the inside of the hull during hull construction (as seen here). Not only is this aesthetically pleasing, it saves work in the future when the hull needs to be re-varnished because if the foot brace rails were held on by screws that went through the hull, the screws would have to be removed prior to sanding/re-varnishing, etc.

Time to finish gluing the seams inside the hull and create the fillets in the bow and stern stems so that the fiberglass cloth will lay smoothly in the hull and not trap air. I will also reinforce the butt seams in the middle of the hull, and then do the saturation coat before fiberglassing the inside of the hull.

The last process on the inside of the deck is to build permanent fiberglass slots for the adjustable thigh braces. This is accomplished by using wooden forms covered in packing tape (so that the epoxy won’t stick to them) to create fillets and shape fiberglass tape into the necessary shape.