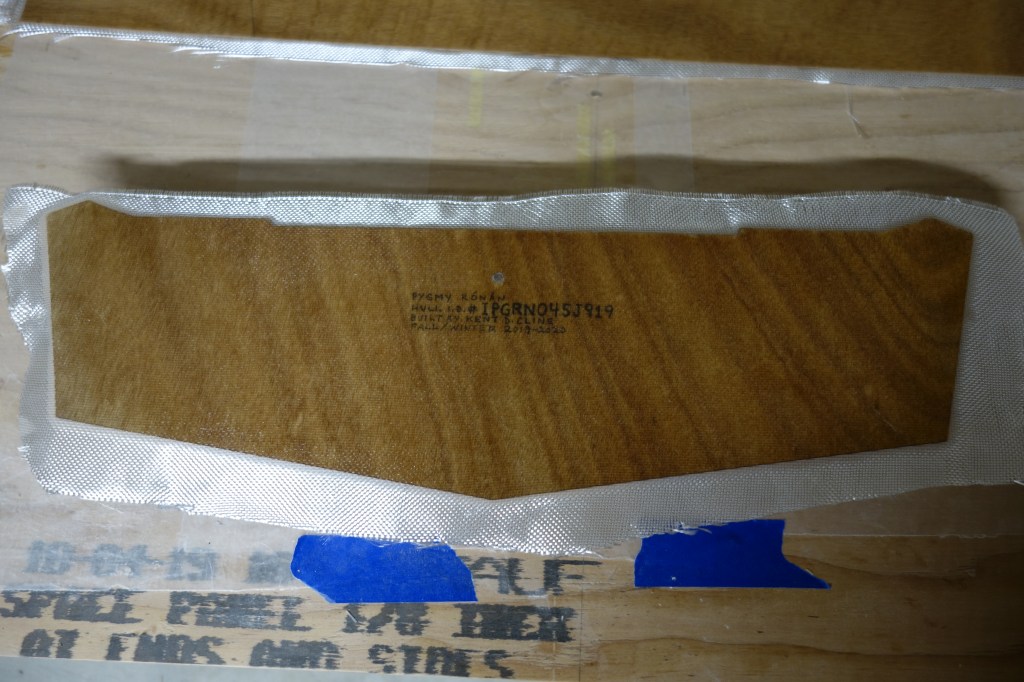

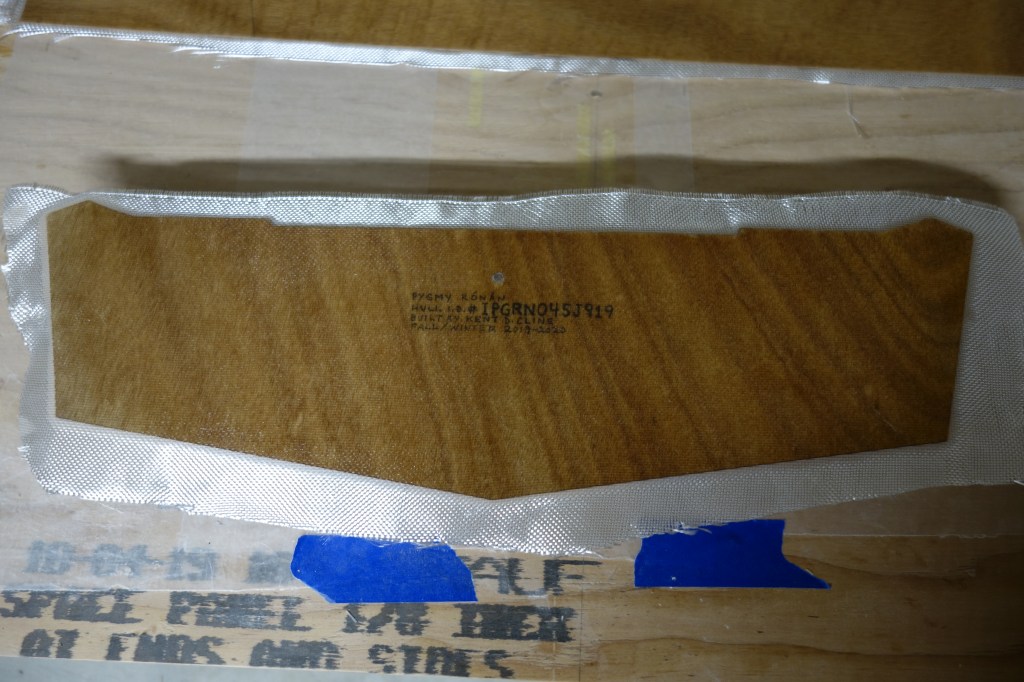

I have time today to fiberglass the bulkheads and the material for the hip braces, to which the back band (seat back) will attach.

I have time today to fiberglass the bulkheads and the material for the hip braces, to which the back band (seat back) will attach.

My plan for the kayak when I got home from work this evening was to glue up the complete lower cockpit coaming, that is, both halves at once, but it didn’t work out that way. I have 24 spring clamps and when I dry fit the lower coaming pieces it looked like 12 clamps on each side would be plenty. But when I got thickened epoxy on one half of the lower coaming and started to clamp it up I could see that I wasn’t getting good squeeze out in places. I kept adding clamps, and finally resorted to Vice-Grips in a couple of places as well, and wound up using 18 of my clamps. I then had a devil of a time cleaning up the squeeze out so that it wasn’t all over the place because the clamps were in my way! I’ll use a bit less epoxy on the second side. I also wound up wasting about an ounce of thickened epoxy because I only glued up half as much as I thought I was going to. Now I have to wait until tomorrow to do the second half. Hurry up and wait! EDIT: After getting some advice from Suzanne at Pygmy, I opted to wait an additional day to remove the clamps and start on the second side. Because there is so much spring tension in the places where the coaming has been forced to conform to the curve of the cockpit apron, I want to be absolutely sure that the epoxy is fully cured. These photos were made on a Friday evening. I will not release the clamps (or the Kraken) until Sunday morning.

While it is on my mind, I want to take a minute to say how gratifying this kayak building process has been so far. I am certain that 99% of the credit goes to John Lockwood and everyone at Pygmy Boats for making such a high quality product, and providing such thorough instructions and excellent support (and 1% to me for carefully reading and following said instructions). From some of the feedback that I have read on the Pygmy Boats website it seems clear to me that many people who first decided to build a Pygmy kayak or boat in order to get a beautiful boat wound up getting something much more. I think that is true for me as well. On re-reading this blog I realized that while I have posted photos and descriptions of the entire process so far, that I tend to spend more time detailing the parts of the build that present challenges or caused problems that have delayed moving forward on the kayak, and as a result, I tend to gloss over the parts that go smoothly and “just work as intended.” I want to acknowledge that the comprehensive design of this kayak kit and the included instruction manual has meant that almost all of the processes in the construction of the kayak so far have gone smoothly. This has been an interesting and rewarding experience. It hasn’t always been what I would call fun (does anyone really think that sanding is fun?), and there have been a few times that it has been stressful because I didn’t know if I was going to screw something up that couldn’t be fixed later, but it continues to be rewarding. And for that I am grateful.

A quick word about building a kayak during winter in the Pacific Northwest in an unheated garage. I have done everything I can to isolate my workspace so that I can use a couple of space heaters to get the temperature up enough for the epoxy to cure, but it has its challenges. I can’t leave the space heaters on 24/7, and would worry if they were left on overnight, or while I am at work, etc. As a result, when the heaters are on it’s 60-65 degrees Fahrenheit in the shop, but when the heaters are turned off, it quickly drops to close to whatever the temperature is outside (averaging around 45 degrees F this time of year). So far, it usually takes a couple of days on average for epoxy to cure enough for me to sand it without it being “gummy” and clogging my sandpaper and risking causing bigger problems. I have read with envy, when other builders say that they built their kayaks in a few weeks from start to finish, and can only imagine that either they know something about epoxy resin that I don’t, or they have a nice heated space in which they can epoxy one day and sand the next. I’ll be lucky if I can finish my boat in 16 weeks, and for me, that’s all down to waiting for epoxy to cure enough to move on to the next step (whatever that happens to be).

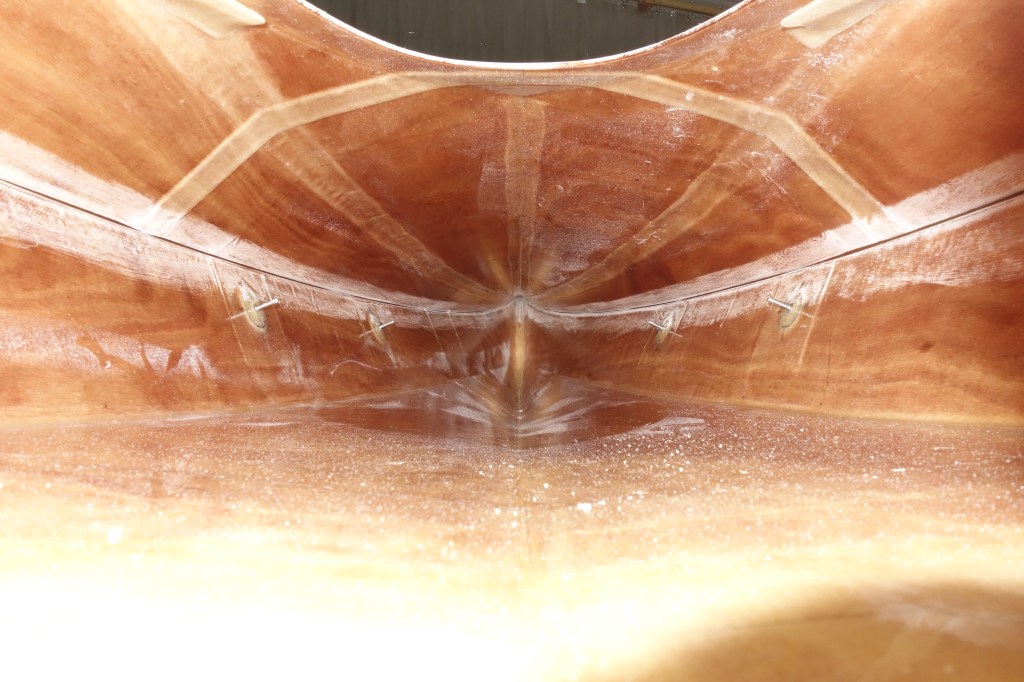

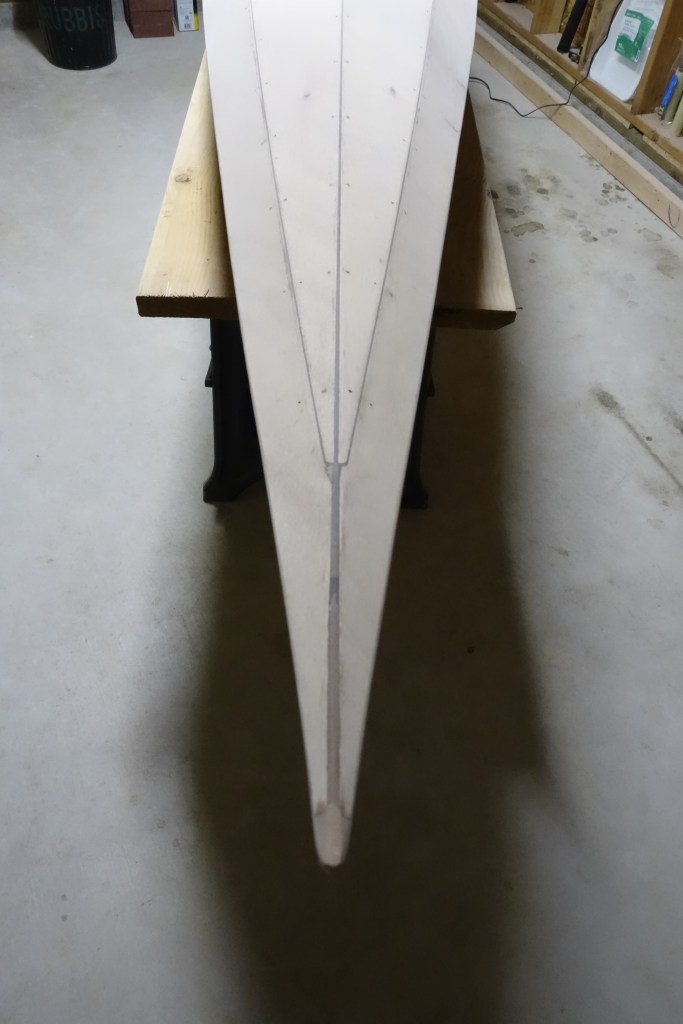

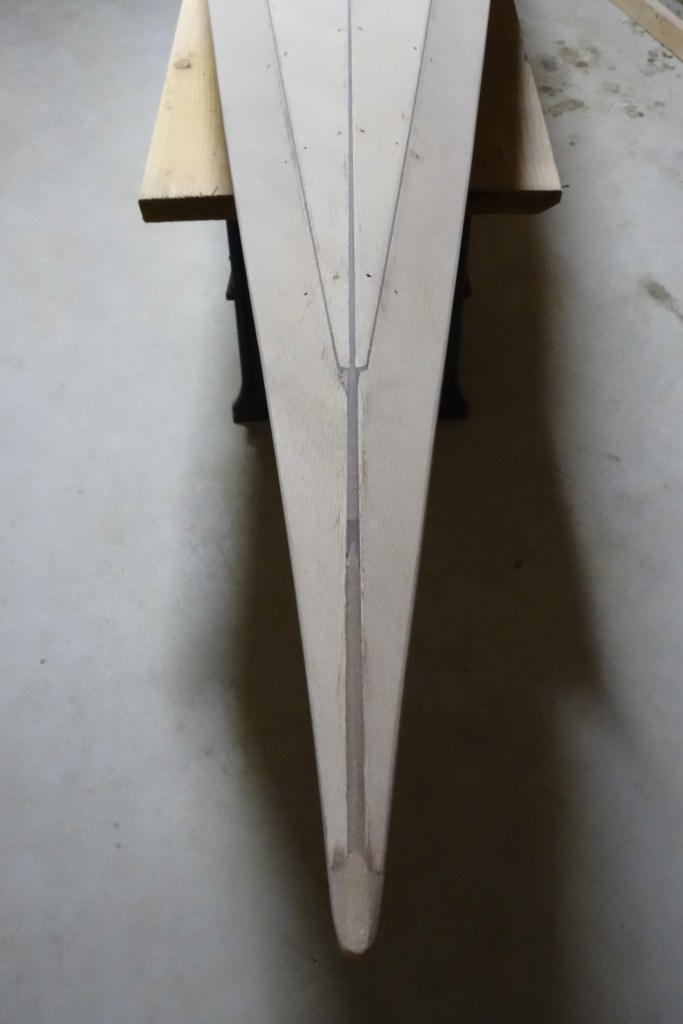

This is the first fill coat of epoxy after fiberglassing yesterday. I’ll apply another fill coat tomorrow and then sand, especially where fiberglass cloth overlaps on the cockpit apron and the hull. Then a final fill coat. If you look closely at the photo above of the bow tip, you can see that I have sanded smooth the bits of fiberglass cloth that were sticking out from the bow tip. Things are coming along. After all of the fill coats and sanding the next step is to build the cockpit coaming. EDIT: My intention was to do another fill coat the day after this post, but as per my comment at the top of this post about working in an unheated garage, this first fill coat wasn’t cured enough to sand yesterday.

Fiberglassing the deck was more challenging for me than fiberglassing the outside of the hull was, and getting the cloth to lay down smoothly on the hull just past the shear seam required a lot of careful attention to detail and a bit of swearing. It came out fine, but it was an hour of focused intensity which I am happy that I don’t have to repeat anytime soon. I found this to be every bit as challenging as getting the fiberglass to lay down inside the hull. I can’t help but wonder if everyone has a bit of a struggle with this or if it’s just me! Oh well. It’s done, and I can move on to the fill coats and sanding. Then the cockpit coaming.

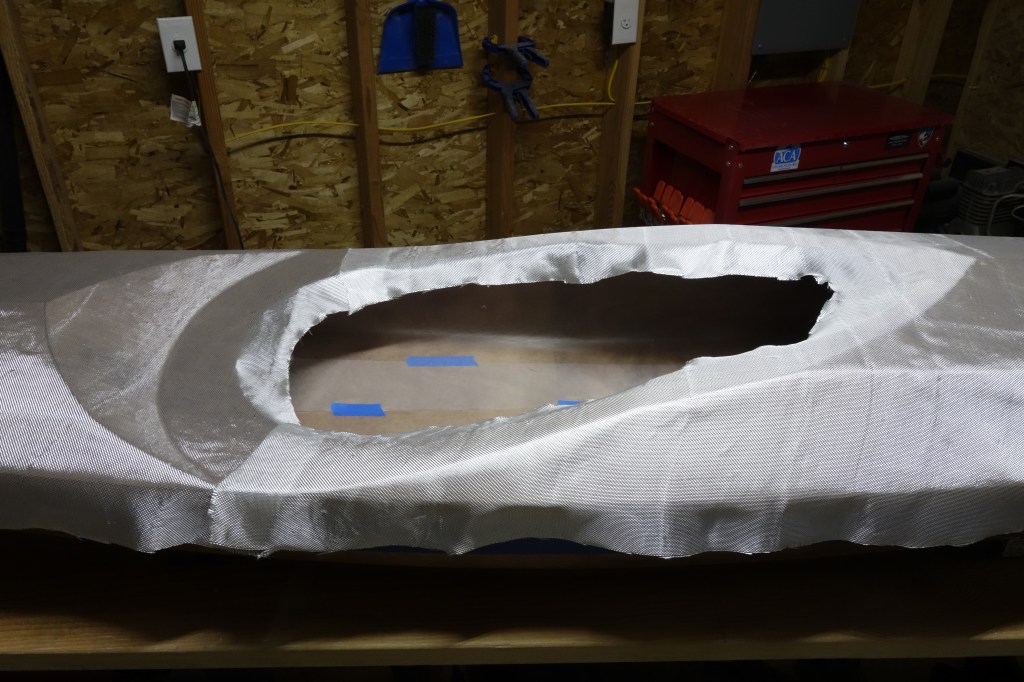

Major milestone. Gluing the deck to the hull! The kayak will be one piece by the end of the day.